CHEVROLET KNOCKS THE C7 OUT OF THE PARK, AND PROCHARGER MAKES IT BETTER!

It goes without saying that the C7 Corvette Stingray launch was likely one of the most anticipated platform launches in recent years. You couldn’t open a magazine, or an Internet browser without hearing about the new Corvette. Needless to say all of us here at ProCharger felt the exact same, and could not wait to get these C7’s running around with some “unnatural” aspirations. So now that the engineering dust has settled, we are pleased to announce the release of the 2014+ C7 Corvette ProCharger Supercharger System.

So here we go … you asked and we listened.

The most rugged bracket possible–

DONE.

A dedicated 8rib drive with the most belt wrap–

DONE.

The biggest and most effective intercooler, with the lowest pressure drop–

DONE.

Easy, OEM-looking install, without cutting or trimming–

DONE.

A system that can go above the standard HP offering–

DONE.

With 20 years of designing supercharger systems under our belt, the energy surrounding ProCharging these C7’s was truly amazing. The C7 system design started as a 100% clean slate approach, with the simple theme of “over engineered” to be used throughout. Obviously we knew that these cars would instantly be in the 650+ HP range, however we knew that it wouldn’t be long before people were pushing the limits of these LT-1 motors well into the 1300+ HP range. Even though not everyone will push these kits past the factory 7psi boost level, its nice to know that everything has been designed to go WELL beyond that, from the bracket design, intercooler, all the way down to every nut and bolt.

This system is not only ready to go beyond three times the LT-1’s base power output, but also was designed to be hands down the easiest Corvette supercharger system install we have ever offered. (4-5 hour install time) So lets start taking a look at each part of the system, and what makes this Procharger system the best bolt on for these new C7 Corvettes.

Bracket System:

Optional Polished Finish

Optional Black Finish

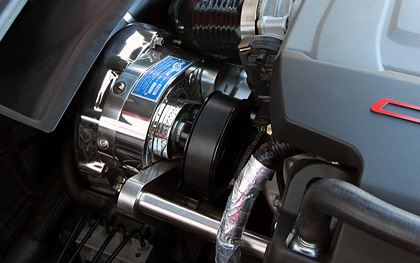

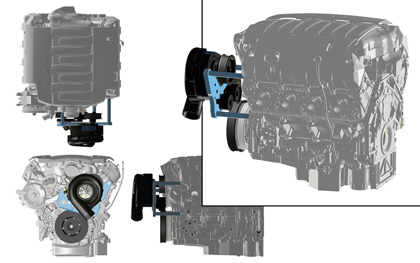

Starting from GM engine CAD models, ProCharger made the CNC chips fly to create a one-piece billet design utilizing existing, robust mounting points on the LT-1 motor for maximum holding force. This system will firmly hold head units ranging in size from a P-1SC-1 up to even an F-2 head unit–that’s right, we said F-2!

Absolutely no relocation of any OEM parts is needed–no fluid systems are opened up, and the ABS module and lines stay in the factory location. This not only speeds up the install, but it also ensures that all factory braking, cooling, and oiling systems on the car work just as GM intended.

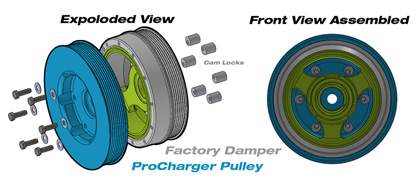

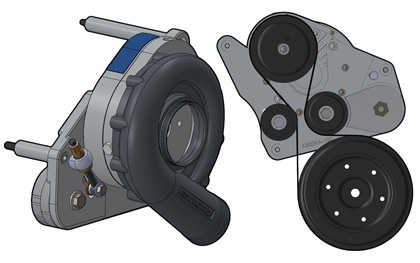

Knowing 1300+ HP C7’s were just around the corner, ProCharger wanted to make sure this system offered an 8-rib dedicated belt drive system out of the gate. Using a patented crank pulley design, we are able to adapt a 8.125″ supercharger drive pulley onto the factory harmonic balancer, without having to drop the steering rack or pin the crank (balancers are already pinned from the factory). The ProCharger crank pulley works by using a system of “cam-locks” to securely grip the factory balancer, taking the load off the crank bolt, and ensuring years of service without worry.

Combining this 8.125″ crank pulley with a multi-position, fixed idler near the supercharger pulley, the system was designed for maximum belt wrap. This ensures maximum belt traction as the power levels of these systems get pushed well beyond the factory 7psi system offering.

Even with the best belt wrap possible, the tensioner system still needs to be up to the task of holding drive power without slippage. ProCharger’s tensioner is unique in design in that its not only spring loaded, but also allows the customer to add as much pre-load adjustment as they want into the belt. This tensioner has already been proven to support 1300+HP when used with dedicated 8 rib belts, so handling the factory 7psi is no stress at all.

You can also change the pulley and 8-rib belt without removing the bracket or the supercharger.

Intercooler System:

GM spent a great deal of time on the airflow design of this new C7, from the front fascia to the inlets for the coolers on the rear fenders. With this in mind ProCharger knew that an off-the-shelf intercooler wasn’t going to cut it, and that something had to be designed specifically for the C7’s horsepower and cooling needs.

During the initial design process, we looked to see if an adequate intercooler could be installed without the removal of the front bumper, however knowing the power levels these C7’s would be pushing, and how easy the bumper is removed (Thanks again GM) it was determined that it wasn’t possible to fit an adequately-sized intercooler without removing the front bumper.

So starting with a fresh core design, the cross flow section was increased in size to eliminate pressure drop as much as possible, while retaining cooling capacity. Just how big is this intercooler you ask? How does 972 cubic inches sound? That’s right, almost 1000 cubic inches of core volume alone, attached to end tanks also designed specifically for the C7.