BLOW-THROUGH CARBURETOR SELECTION

When selecting a carburetor for your ProCharged blow-through application, as with naturally aspirated engines, less is generally more. A carburetor can be sized according to your engine’s airflow and resultant power output. Even though a larger than recommended carburetor may offer some increase in peak power, it will likely cause the engine to be less responsive at low RPM and result in drivability unacceptable for cars that will be street driven.

Preparing a carburetor for use in a blow-through application typically involves few, if any modifications. Among those needing no modification are Holley’s HP series carburetors which are designed with no choke assembly and generally equipped with Nitrophyl floats from the factory.

But what if you have Holley’s most popular carb … the Double Pumper? For standard Double Pumper carburetors, the choke assembly should be removed to provide optimal airflow and performance when used with a carburetor bonnet. Additionally, the brass floats (which will collapse under boost) must be replaced with Nitrophyl floats (available from ATI, or Holley). With only the modifications listed above, Holley Double Pumpers (when properly jetted) will typically flow enough fuel to support 1 hp per rated cfm of airflow. Single carburetor applications exceeding 1 hp per rated cfm may require additional modifications such as resizing main wells and power valve restrictions, changing boosters and emulsion circuit recalibration.

Benefits of Carburetor Fuel Systems

Although some used to question the viability of “blowing through” a carburetor designed for use in atmospheric conditions, carburetors (with a few simple modifications) have been used successfully in blow-through applications for decades. This includes applications with boost levels in excess of 25 psi and power levels in excess of 2,500 HP. The key benefit of using a carburetor, as opposed to EFI, is the charge cooling effect that is best summarized in this quote from Hot Rod magazine: “Working under the laws of latent heat of evaporation, an engine equipped with a carburetor will exhibit substantially cooler charge temperatures when it arrives at the intake port in the cylinder head. A temperature this cool means the cylinders are being fed a much denser oxygen charge and producing at least 5 percent more power.”

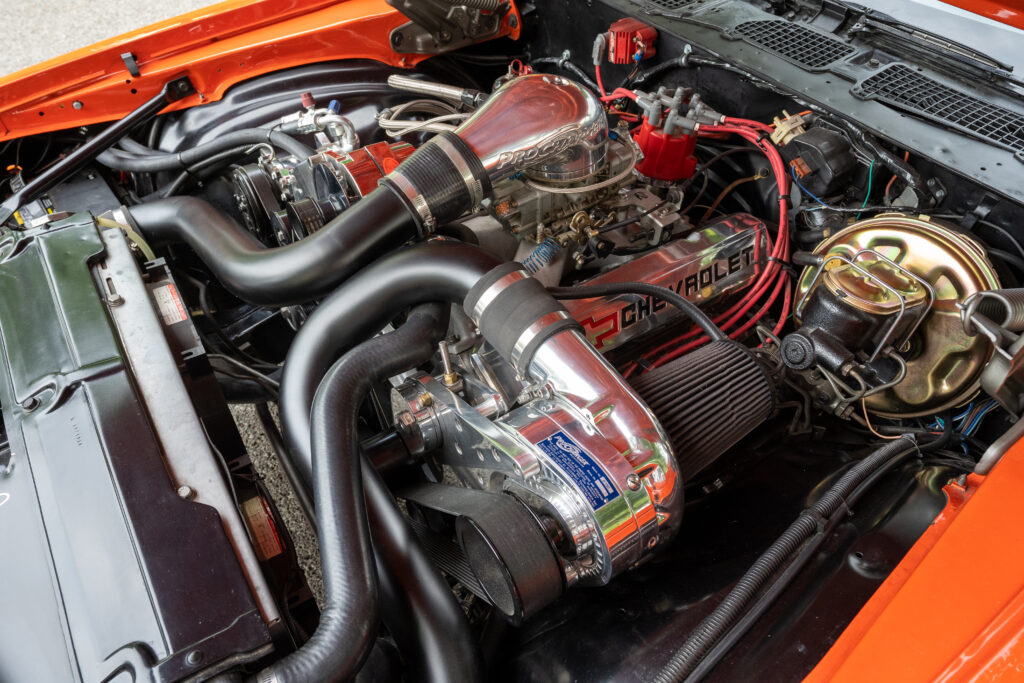

Carb Hat Design

Although an “ideal” carb hat configuration would have the air entering vertically from several inches above the mouth of the carburetor, hood clearance issues often don’t permit it. Our carb hat designs allow air to enter the carburetor with minimal horizontal air movement across the top of the venturi. This ensures that a uniform, turbulence-free airstream passes through the booster, allowing it to function properly. Some other hat designs deliver inconsistent results when placed in various positions, but our design assures that proper bowl pressures are maintained, providing consistent performance on ProCharged, carbureted applications.